Curing control using Tangent Delta

The benefit of knowing the curing

Control and optimize the quality of enameled wire

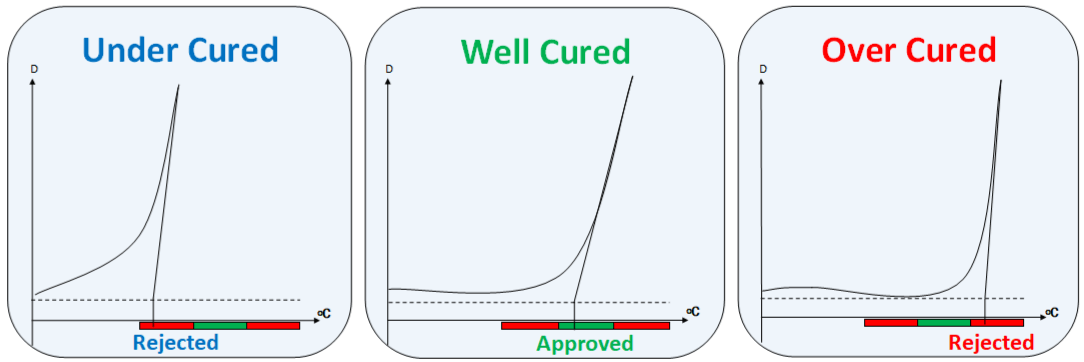

Optimizing the processes by knowing and controlling the parameters within the production of enameled wire is essential for the economy when manufacturing this product. The Tangent Delta tester from DSE in Denmark delivers all the information needed to optimize and control many processes. The measuring data is compressed and displayed in an entire curve, showing the Tangent Delta as a function of the temperature. This method is the ultimate way of making a fast, accurate, and reliable determination of the enameled curing and simultaneously showing any residual solvents or additives in the insulation.

Both residual solvents and the curing state greatly influence the enameled wire's temperature index, lifetime, and physical behavior.

This is an example of a PU enamel. Other enamels have different shapes.

Fast, accurate, and well-proven test method

Using the dissipation factor method, the Tangent Delta testers(TgD) analyze the enamel's quality and physical properties.

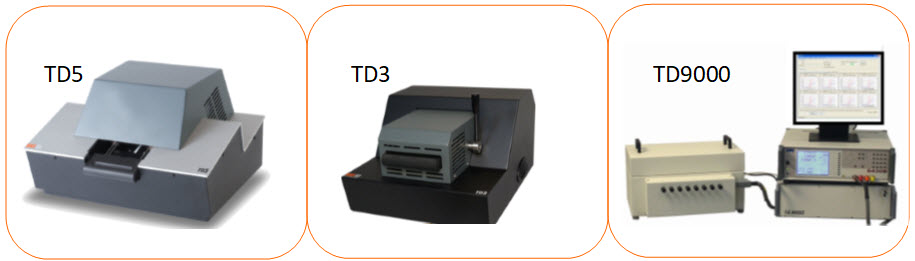

The product range contains the following models:

- The TD9000 TgD tester is still available after 30 years.

- The TD5 TgD tester is the world leader in performance and has been a real workhorse for decades.

- The TD3 TgD tester is built on the same technology as TD5 and is a clear winner in price and performance.

All Tangent Delta testers calculate an entire curve for the D value (loss factor) as a function of the temperature.

FAQ

What is a Tangent Delta Tester?

A Tangent Delta Tester (TgD) is an instrument used to analyze the quality and physical properties of the enamel on wires by measuring the dissipation factor (Tangent Delta) as a function of temperature.

Why is Tangent Delta measurement important for enameled wire?

Tangent Delta measurement provides fast, accurate insights into the curing degree and quality of the enamel. Proper curing is essential for ensuring the wire’s performance, temperature resistance, and lifespan.

What information does a Tangent Delta curve provide?

The Tangent Delta curve reflects the curing state, presence of residual solvents or additives, and helps identify the type of enamel used. This allows manufacturers to optimize production and ensure reliable quality.

What are the main applications of TD5 and TD3 Tangent Delta testers?

TD5 is suited for routine quality control of both round and flat enameled wire, offering high-accuracy, high-speed measurement, and multiple user-friendly features. TD3 provides similar performance in a compact, portable, and cost-effective format.

How are Tangent Delta tests performed?

A sample is gradually heated in a controlled oven, and the Tangent Delta value is measured and automatically plotted. Operators use the resulting curve to judge the quality and curing of the enamel.

What standards are the TD5 and TD3 testers compliant with?

Both testers comply with IEC 60851-5, which outlines methods for measuring electrical properties of enameled wires.

How does knowing the curing degree benefit wire manufactures?

Accurate control and optimization of enamel curing reduce production costs, minimize scrap, and ensure consistent product quality for customers.

Who should use Tangent Delta Testers?

Manufacturers and end users of enameled wire benefit from using Tangent Delta testers for incoming inspection and in-process quality assurance to verify that the enameled wire meets required standards.

Are Tangent Delta Testers suitable for all types of enameled wire?

Yes, these testers are designed to handle various types and shapes of enameled wires, including both round and flat profiles.

Contact our sales department for more information.